Common roasting machine problems - a podcast by Scott Rao

from 2018-09-16T13:56:04

I’ve worked with several hundred roasting machines over my consulting career and have experienced a troubling problem: manufacturers often deliver roasting machines with what I would consider defects, and then refuse to acknowledge the problems or fix them for customers. I won’t name companies in this post, but would like to discuss a few of these recurring problems here in the hopes that roasting-machine manufacturers address these issues soon.

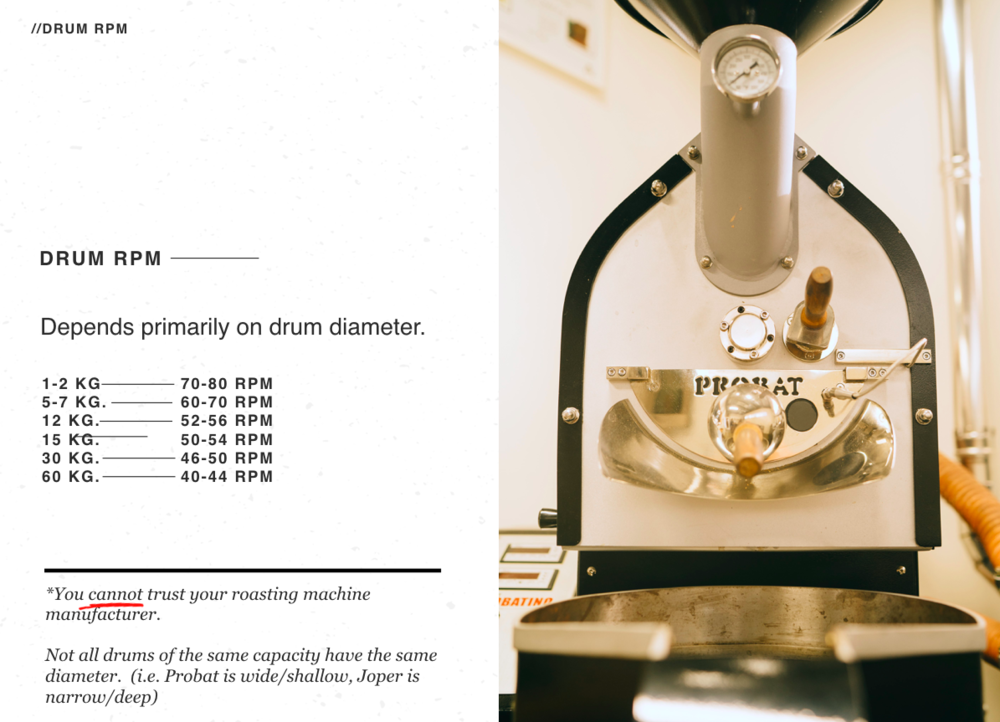

DRUM RPM

The most common inconsistency I have noticed in delivered machines has been drum-RPM count. There are two issues around drum RPMs and new machines: delivered machines having consistently suboptimal RPM levels, and delivered machines of a particular model from a given company having wildly different RPMs. I understand that manufacturers may disagree with me about appropriate RPM levels; that’s fine. But when I see a 1kg machine delivered with 50 RPM or a 12kg machine delivered with 35 RPM, or a 15kg machine delivered with 70 RPM, we’ve crossed the line from debatable to unreasonable.

In my seminars I often share this table of RPM recommendations. The numbers are merely estimates. Please don’t think that if I recommend 50—54 and your machine clocks in at 55 that you have a problem; you don’t. Please note that I cannot recommend a precise RPM level for all machines of a particular size because the proper RPM level depends on drum diameter, and two different models of 15kg machines, for instance, may have quite different drum diameters. For example, a 15kg Joper has an unusually long, small-diameter drum, while a Probat UG15 has an unusually shallow drum with a large diameter. All else being equal, the Joper’s drum RPM should be higher.

INCONSISTENT RPMs

It’s tempting to assume that machine manufacturers are all experts at roasting, but few are. For instance, one US manufacturer repeatedly tells customers that ROR crashes don’t matter, they confound baking with roasty-ness, and they seem to think that ROR flicks at the end of roasts are “normal” and not a problem. I, and every competent roaster I’ve ever worked with, couldn’t disagree more. The same company offers costly roasting classes, which should give readers pause. One decades-old machine manufacturer routinely delivers 12kg machines with drum RPM ranging from 35—55. Beyond the fact that 35 RPM is unreasonably low for a 12kg machine, this company must (I hope) have some RPM target, so why in the world are they willing to ship machines with such disparate RPM levels? That company has yet to agree to fix any of those 35-RPM machines and claims that 35 RPM on the 12kg machine is “normal” while also shipping some machines at 55 RPM. Contrast that with an experience I had this month with Reyes Tellez at Probat USA: I had just begun working with a new client on his Probat P12. I asked the client to fill out a consultation intake form, which included measuring the machine’s RPMs. It turns out the machine’s RPM was 67 instead of the 55 that both Reyes and I agreed was optimal. I emailed Reyes a video of the drum turning for one minute. A day later, Reyes acknowledged the problem, said he suspected there was a fault in the generator, and overnighted new generator to the client. That fixed the problem immediately. Every company makes mistakes or delivers machines with faults; that doesn’t bother me. It bothers me, and should concern everyone thinking of purchasing a roaster, when companies refuse to acknowledge or fix those faults.

OTHER FEATURES

Inconsistencies often exist with other roasting-machine features. For example, one major brand often delivers machines with excessively high airflow, several offer burners that are woefully underpowered for their intended batch sizes, and many manufacturers still provide temperature probes too slow to produce the quality of data necessary for expert-level roasting.

SOME COMPANIES ARE LISTENING

Whenever I get a new client with a poorly tuned machine, I ask him or her to tell the manufacturer. For years, the manufacturers would almost always respond by asserting their expertise and then dismiss the customers’ concerns. I’ve had the complete opposite experience with Mill City Roasters. Steve and his crew have not only added new features every year to their machines, but they have considered and tested every recommendation I have made, and they have implemented almost all of them. Although I have no financial relationship with Mill City (other than them selling my book and my buying a machine from them— at retail), I’ve enjoyed sharing my experience with them because it’s a joy to work with a company willing to listen, test, and improve continually.

I see it as part of my job as a consultant to ensure manufacturers get feedback from both myself and from clients, and to advise clients to buy from companies that are open to feedback and determined to improve. Through that process it has become easier to know which companies take responsibility for their products and for their customers’ satisfaction.

***

Thanks for reading. I respectfully request that comments not directly criticize any particular brands; let’s please focus on features and experiences, and not on brands or models.

POST-PUBLICATION NOTE: Some readers have expressed confusion about whether the RPM recommendations refer to batch sizes or machine capacity. For instance, they are wondering if a 7-kg batch in a 15-kg machine calls for the same RPM as that recommended for a 7-kg machine. The answer is no. To be clear, the RPM recommendations are based on machine size and drum diameter, not batch size. Whether it is beneficial to adjust up or down a few RPM when doing half batches is a separate discussion.

Further episodes of Q

Further podcasts by Scott Rao

Website of Scott Rao