The Most Important Thing Few Roasters Bother to Do - a podcast by Scott Rao

from 2017-04-09T16:09:21

In the mid-90s one of my staff had a fire in the drum while roasting. We hadn’t previously discussed proper fire procedure, and he opened the discharge door (please don’t do that), spilling the beans and flames into the cooling bin. The flames were higher than his head and he put the fire out using a fire extinguisher. We spent the next 12 hours scraping clean the cooling bin fan and tray, and hammering the warped cooling bin back into a semi-flat shape. He reads this blog, and I know the memory is making him cringe right now :).

After that event I got serious about roaster fires. I’m writing this post in the hope that you, dear blog subscriber (you’ve subscribed, haven’t you?), will be smarter than I was, and get serious about roaster fires before, not after, your first fire.

When I’ve asked clients what they plan to do in the case of a fire, they usually answered something like “I don’t know” or “I’ll spray the fire extinguisher through the trier hole.” Spraying the fire extinguisher through the trier hole will likely work, but it’s awkward to do, and I doubt you really want to coat your drum with whatever chemicals are in your fire extinguisher. There are better solutions.

Every roasting machine should have a water line hard-plumbed into its face plate and chaff cyclone. They're part of a long list of features I wish small-roaster manufacturers would get smart about. A fire suppression system is also one of many features standard on larger machines but rare on smaller machines. Unfortunately for us, selling small roasters has been an easy business for many years now, and most manufacturers have been complacent about machine design.

Ideally, install the face-plate water line's-shut-off valve in a location that is easy to access from where you stand while roasting. The water line should have a spray nozzle on the end, and you may need to purge the spray nozzle of chaff and other debris at the beginning and end of each roast day. A quick squirt will suffice, and will not harm your drum.

The second water line should be plumbed into the chaff collector (cyclone), as that is where most roaster fires occur. The odds are much higher you will have to spray water into the chaff bin than the roasting drum at some point, but being ready for a fire in both locations is prudent.

cyclone with water line plumbed

Unlike most insurance policies that must be paid for each year, installing two water lines into your roasting system is a one-time expense of perhaps $300 USD that will protect your business’s most valuable machinery for decades. If you’re hesitant to spend the money, think of it as a $10-per-year expense to protect your roaster for the next 30 years.

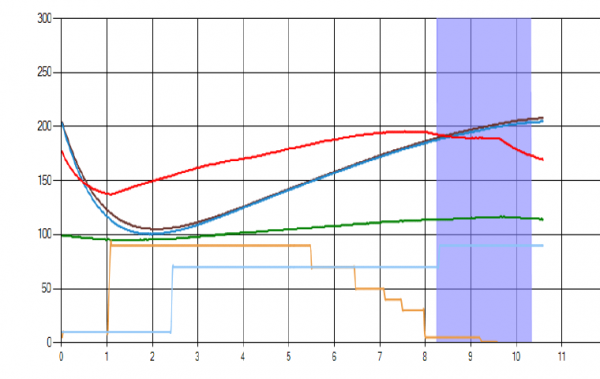

You get bonus points for tracking the cyclone temperature with your roasting software and extra bonus points (I know, can you believe it?) for setting a high-limit alarm on the thermocouple. You’ll find the chaff-collector temperature relatively stable during roasting, but if the temperature begins to rise out of its usual range, a fire may be imminent.

roasting screen with cyclone temperature curve

Finally, here's a sneak peak at a prototype of a water-scrubber-cyclone system that does a great job of cleaning roasting smoke, and of course would also prevent a chaff fire from ever occurring.

vortx prototype

Do you have a story about a roaster fire? I'd love to hear it.

Thanks for reading.

Further episodes of Q

Further podcasts by Scott Rao

Website of Scott Rao